Less dust and noise with the Dustex dust separator

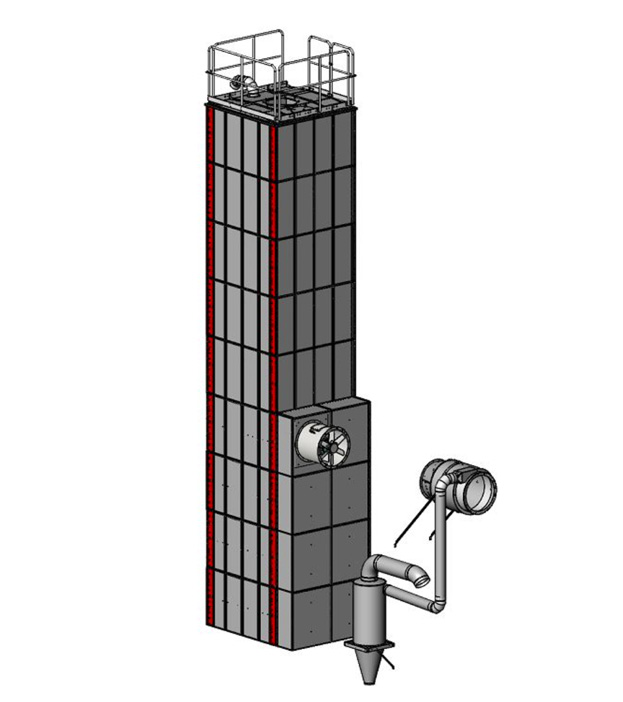

The Antti Dustex dust separator is the newest product from our product development. Dustex removes dust and debris from the exhaust air of the dryer, so the air blown into the dryer's surroundings is almost clean.

Dustex is based on years of research, thanks to which it is exceptionally effective in removing dust and reducing the noise effects of drying. Dustex is designed to meet our customers’ needs, and it has also been developed in cooperation with our customers.

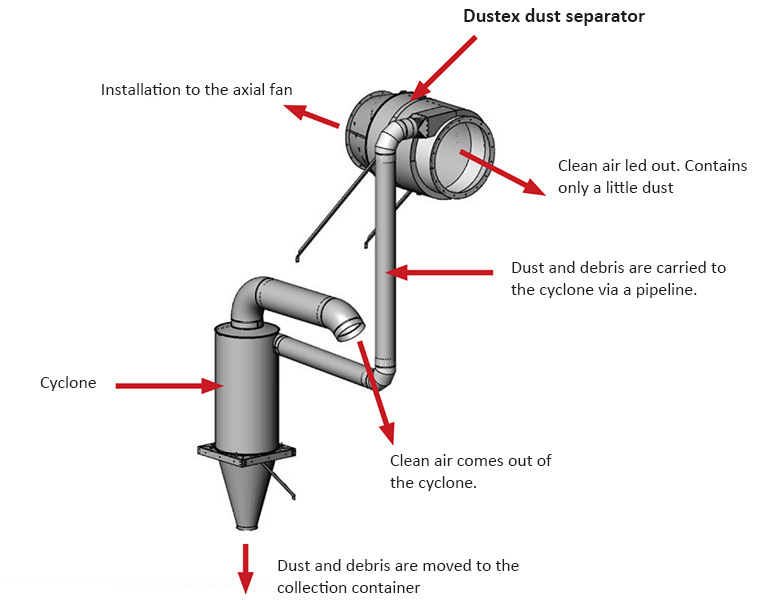

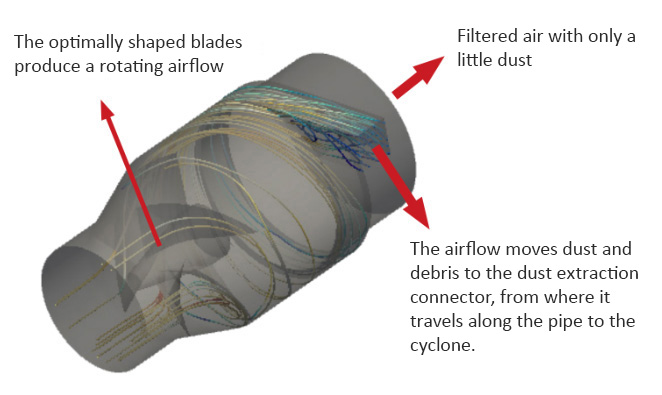

Dustex is connected to the dryer’s axial fan, which absorbs air from the dryer and blows it outside. Dustex delivers an optimal rotating airflow that drives even small dust particles into the Dustex dust extraction connector. Thanks to Dustex, grain husks and dust no longer spread into the surrounding area of the dryer.

Cleaner environment

At its most harmful, exposure to grain dust can cause various symptoms for the farmer, such as chronic cough, shortness of breath and skin irritation caused by grain dust. Antti Dustex is the solution to this invisible problem.

Quiet environment

Customer experiences are telling: the yard is cleaner and less noisy. Dustex reduces the noise transmitted around the dryer by up to 6 decibels.

You'll see the difference

- Collects dust and debris from the exhaust air of the dryer – a cleaner and healthier environment

- Reduces noise – a more pleasant environment

- Installation to the axial vacuum

- Can be retrofitted to existing Antti dryers

Dustex is based on precise product development

The rotating airflow produced by Dustex moves dust and debris to the discharge outlet. The shape of Dustex’s blades is aerodynamic. The blades have been designed with extreme precision. We have used Cfd flow modelling as an aid to model how debris moves into the cyclone. When the blade shape is optimised, debris removal is efficient.

The shaped blades make filtering more efficient and remove almost all debris.

Cyclone does the final sorting of the debris

From the pre-cleaner and Dustex the impure air is led through a pipe into the cyclone, where the debris and dust are separated from the air. The pipe on top of the cyclone is used to lead the air outside, and the conical part at the bottom is used to direct the debris and dust into the waste bin/waste room.

Centrifugal force is used in the cyclone. In the cyclone, dusty air is rotated, and the centrifugal force generated forces the dust particles towards the cyclone wall. Air flows spirally towards the bottom of the cyclone, causing the dust particles to be hurled against the cyclone wall and drift to the bottom of the cyclone.

The cyclones come in two sizes:

Ø 630 mm – used in Dustex and Pre-Cleaner (2,2 kW)

Ø 900 mm – used in Pre-Cleaner (4 kW)

Dustex and Cyclone operating principles